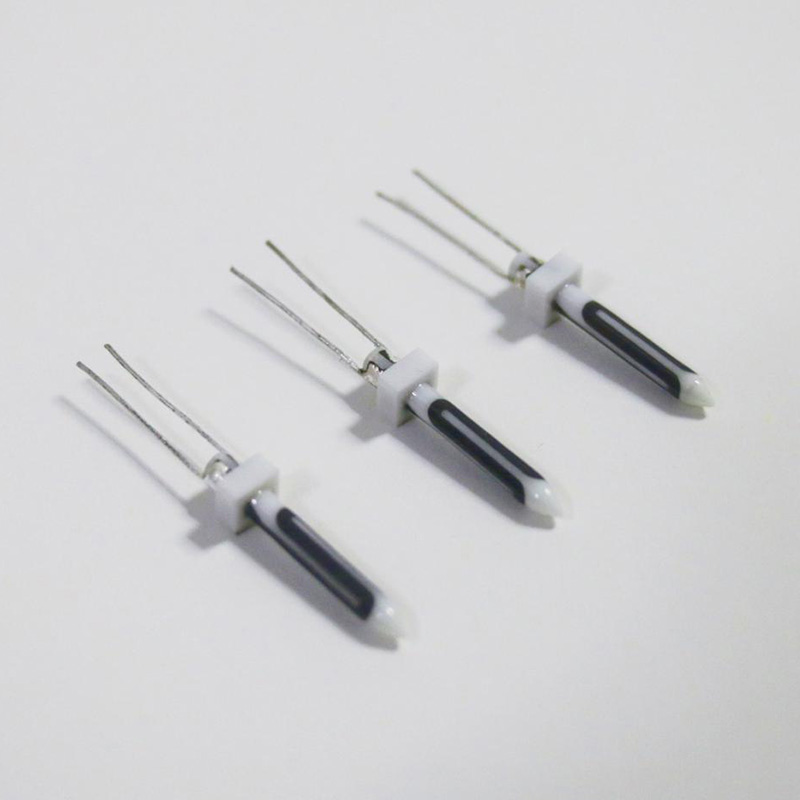

Zirconia Rod Ceramic Heating Element yeDC voltage E-fodya mudziyo

Nhanganyaya ye Keycore Ⅱ (HTCC ZCH) yekushisa kwakanyanya co-fired zirconia heat element

Kukurumidza kupisa kwekushisa

Mukati mhango dhizaini

Zironia zvinhu

Electrode yakakwirira tembiricha sirivha brazing

Simba rekukotama rinogona kusvika 15KG. Yakakura zvakapetwa katatu tip zirconia heater (yeIQOS) uye neka1.5 hombe pane tip alumina hita.

Kuderera kwesimba rekushandisa, 29% yakaderera pane Keycore I

Kupisa nekukasira, zvichienzaniswa nealumina Keycore I, inokurumidza 7.5 masekondi kusvika ku350 ℃, kupisa nekukurumidza kwakawedzera ne1.7 nguva.

Tembiricha yeFlange yakadzikira, 30seconds mu350degrees, tembiricha yeflange isingasviki 100 ℃.

| Diameter | 2.15±0.1mm |

| Urefu | 19±0.2mm |

| Heating Resistance | (0.6-1.5)±0.1Ω |

| Kupisa TCR | 1500±200ppm/℃ |

| Sensor Resistance | (11-14.5)±0.1Ω |

| Sensor TCR | 3500±150ppm/℃ |

| Lead Soldering Withstand Temperature | ≤100℃ |

| lead tensile force | (≥1kg) |

Mamiriro ekuyedza: iyo voltage yekushanda ichaita kuti tembiricha yepasi yechigadzirwa isvike 350 madhigirii, uye wozoyedza tembiricha yeflange mushure me30S yekugadzikana.

Iyo flange tembiricha ye Keycore II (HTCC ZCH) yakadzikira kana ichishanda. Iyo flange tembiricha mushure memasekonzi makumi matatu ekuchengetedza tembiricha ye350 ℃ pamhepo inoshanda ye3.7v haina kupfuura 100 ℃, nepo iyo yeKeycore I iri kutenderera 210 ℃ pasi pemamiriro akafanana.

Ceramic heaters ine zvinotevera maitiro:

Kugadzikana kwekushisa kwepamusoro: Ceramic zvinhu zvine kunaka kwekushisa kwepamusoro uye zvinogona kuchengetedza kushanda kwakadzikama munzvimbo dzekushisa kwepamusoro, saka dzakakodzera nguva dzekushisa kwepamusoro.

Corrosion resistance: Ceramic zvinhu zvine corrosion yakasimba kuramba, zvinogona kushanda mune imwe corrosion media, uye inokodzera kudziyisa zvinodiwa munzvimbo dzakakosha.

Insulation performance: Ceramic zvinhu zvine yakanaka yekuvharisa zvivakwa, izvo zvinogona kudzivirira zvinobudirira kubuda uye kugadzirisa kuchengetedza kuita kweheater.

Uniform heat: Ceramic heaters inogona kuwana yakaenzana yekudziya kupisa, kudzivirira kupisa kwenzvimbo kana kutonhora, uye yakakodzera nguva dzinoda kupisa kwakafanana.

Kuchengetedza magetsi uye kuchengetedza kwezvakatipoteredza: Ceramic heaters inowanzova nepamusoro pesimba uye inogona kushandura simba remagetsi kuita simba rekupisa nepamusoro-soro, nekudaro kuderedza kushandiswa kwesimba uye kusangana nezvinodiwa zvekuchengetedza simba uye kuchengetedza kwezvakatipoteredza.

Hupenyu hurefu: Nekuti zvinhu zveceramic zvine kumira zvakanaka kwekupfeka uye kugadzikana, hita dzeceramic dzinowanzova nehupenyu hurefu hwebasa.

Kazhinji, maceramic heaters ane hunhu hwekudzikama tembiricha, corrosion resistance, insulation, yunifomu yekudziya, kuchengetedza simba uye kuchengetedza kwezvakatipoteredza, uye hupenyu hurefu, uye inokodzera kwakasiyana maindasitiri nedzimba kupisa nguva.